Vacuum bottles are professional cosmetic containers that have their own advantages in use and features in filling. A vacuum bottle is a guarantee of hygiene and safety of a cosmetic product; the contents of the bottle are protected from oxidation because air does not penetrate inside. The packaging allows you to use the cosmetic product as much as possible without residue.

Externally, a vacuum bottle resembles a cylinder with a pump dispenser, which is covered with a lid on top. Inside, this device is somewhat more complicated - a special valve and pump that prevent air and dust from entering the bottle. This bottle is supplied as a set consisting of the container itself, the head part (dispenser) and the cap.

Externally, a vacuum bottle resembles a cylinder with a pump dispenser, which is covered with a lid on top. Inside, this device is somewhat more complicated - a special valve and pump that prevent air and dust from entering the bottle. This bottle is supplied as a set consisting of the container itself, the head part (dispenser) and the cap.

It is important to follow the rules for filling a vacuum bottle!

1. Bottle filling technologies

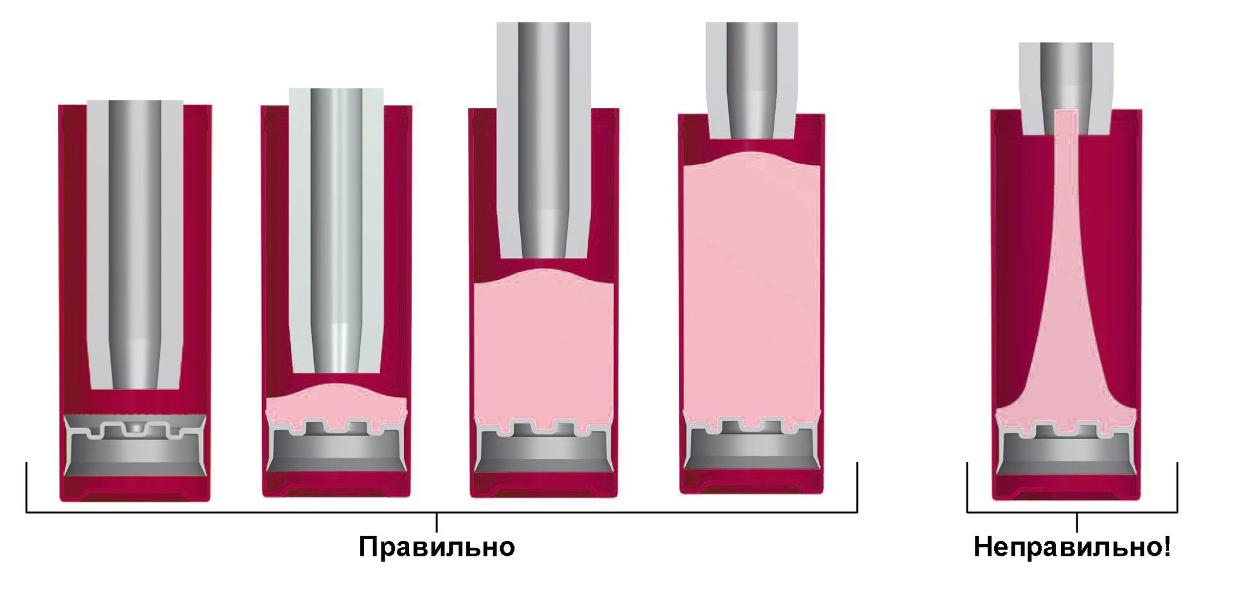

At the beginning of filling, the nozzle must be immersed in the container; a submersible nozzle can be used, which is raised during filling, or filling can be done by lowering the container.

The immersion stroke and lifting of the filling nozzle must be adjusted depending on the viscosity of the product to ensure that the container is filled without introducing air.

Care must be taken to avoid air with high viscosity products accumulating and forming on top of lower viscosity products.

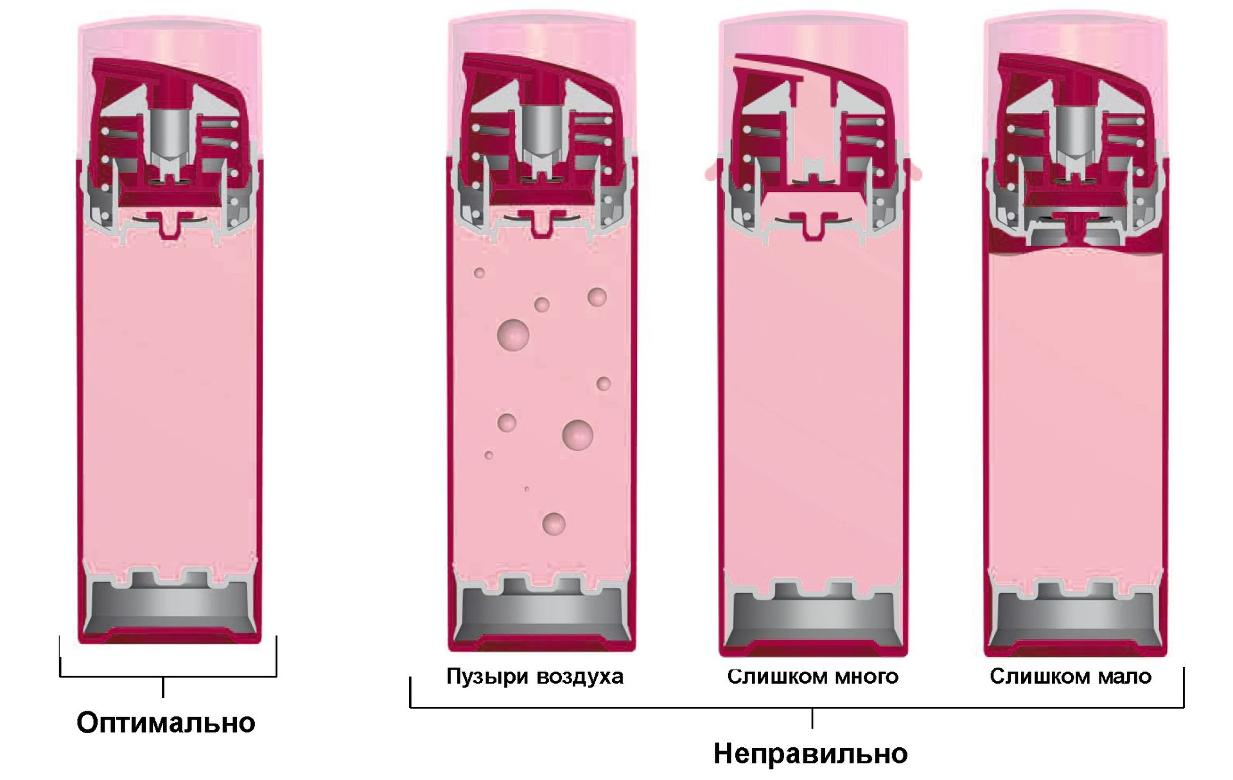

2. Bottle filling level

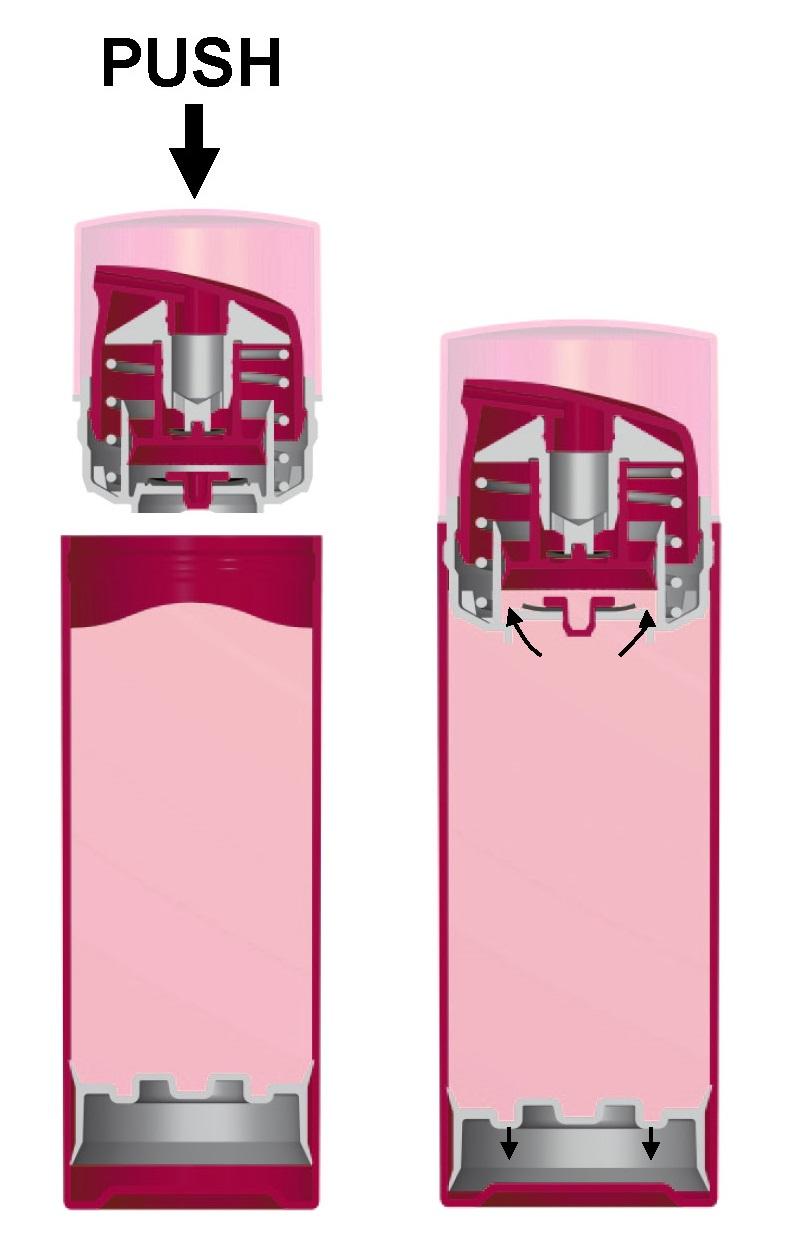

3. Closing

After filling, the head part is installed and pressed vertically downwards. When the head part is latched, the product enters the open pump chamber. The piston moves down to compensate for the product fill level error. Once the dispenser is assembled, the product must be present in the pump chamber.